Can autonomous robots help reduce the cost of the last mile?

The demand for last-mile deliveries is increasing with the rapid growth of eCommerce, however the last mile of delivery remains expensive.

Customers, on the other hand, demand fast deliveries and convenience – and aren’t willing to give up either: 61% of them would switch providers to save on delivery costs, while 57% would find an alternative retailer if they weren’t satisfied with a previous delivery. The available choices of delivery slots are also at the top of customers’ priorities, along with real-time updates on deliveries.

Because of this, retailers are often subsidizing deliveries, or sometimes, absorbing the costs entirely. For logistics providers, this means that offering a service that is as competitive as possible is key for retaining partnerships with online stores and platforms, big and small ones alike.

How can logistics companies solve this riddle and provide delivery options to their customers that are both cheap and convenient?

Are autonomous last-mile delivery robots the answer, and if yes, when can they become an alternative to current delivery methods?

In this article, we’ll discuss these questions and see what are the possible answers.

The real costs of the last mile

While the cost of the last mile is hugely location-dependent, there are a few estimates we could use.

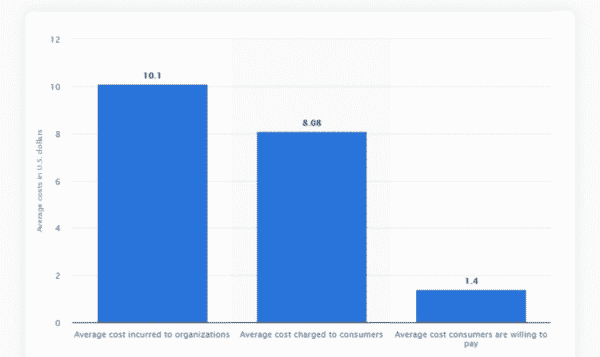

In 2018, last-mile delivery cost approximately $10/parcel to businesses, of which $8 were charged to customers; customers, however, were willing to pay significantly less: $1.4.

(Source: Statista)

DispatchTrack puts the estimated price at a similar value: around $10.

While these prices can (and will) evolve, and are probably even higher today, they give us a good benchmark of how much the last mile costs to retailers vs. how much customers are hoping to pay. And indeed, with free deliveries becoming the norm established by giants like Amazon, customers are price-conscious and unwilling to let go of cheap deliveries.

Additionally, the last mile is the most expensive stretch of the journey of a product to its final destination: Estimates vary, but according to Insider (formerly Business Insider), the last mile amounts for 53% of the total delivery costs.

A multitude of factors impact the cost of the last mile:

- Wages, gas, vehicles: All the direct costs that cover wages, gas, and vehicles (plus repairs) are the most obvious part of the equation – and the costs of the last mile are bound to increase with higher prices for gas; additionally, at the moment, there’s a shortage of labor

- Lower average speeds: In cities, driving speed limits are lower and traffic conditions can further lower the distance a driver is able to cover in an hour

- Frequent stops: To deliver to customers in urban areas, drivers need to stop often, which slows them down; additionally, finding a suitable location to stop or park in busy areas can be a challenge

- Unsuccessful deliveries: When customers aren’t available to receive a parcel, it needs to be delivered to a different location or on the next day – which results in additional costs; according to Statista, the average costs per failed delivery were $17.20 in the US and €14.69 in Germany in 2020

- Returns: Customers expect to be able to return products free of charge and be reimbursed or receive a replacement easily and without paying extra for shipping

- Lost or damaged items: If parcels are lost or damaged, this adds to customers’ frustration and the costs associated with recovering or reimbursing them

On the other hand, delivery speed is also a key consideration for customers: According to Atos, 58% preferred same-day delivery, while 38% prefer expedited delivery (not on the same day); speed, however, also drives costs up, because it requires an additional operational capacity and incurs extra overhead costs.

However, to balance this out, it’s important to note that 70% of customers are willing to wait for a longer and cheaper delivery. Or, otherwise said, cost remains one of the most important considerations.

What are some of the ways to reduce delivery costs?

Although it’s difficult to estimate the exact cost of the last mile, one thing is certain: It’s expensive and, at its current setup, it’s particularly vulnerable to fluctuations of fuel costs.

So, what are some of the ways to ease that tension? There are a number of possibilities at different stages of development.

- Crowdsourced alternatives: Crowdsourced alternatives, where couriers use their own means of transportation to deliver goods, are becoming increasingly popular, especially for the delivery of hot meals (think FoodPanda, Deliveroo, UberEats). Arguably, however, this exposes vulnerable populations to worsening working conditions as startups mature and venture capital dries up.

- Parcel lockers: Centralized parcel lockers have been spawning in cities in the past few years, offer convenience to customers, and enable logistics companies to optimize costs by aggregating parcels in a single location, similarly to delivery kiosks. DHL, USPS, local postal services, and Amazon are some of the examples that come to mind.

- Route planning and optimization: Another alternative enabling logistics companies to provide competitive costs to retailers is to optimize routes with the help of AI- and ML-powered applications. These can be used either for manned or unmanned delivery options (human couriers or robots). Companies like Upper, Inc. and OptimoRoute offer applications that optimize routes for logistics providers.

- More accurate delivery times: Failed deliveries are very costly, so reducing them is one of the best ways to increase efficiency. If customers are able to get an accurate estimate of the delivery time of a parcel (and change it if necessary), they’re much more likely to also be available and be able to receive it. With the help of applications that communicate location or ETA information to customers, the accuracy of delivery times can be improved.

- Self-driving delivery cars or robots: Autonomous delivery vehicles are another promising solution to the challenge of last-mile delivery, although they’re still in their early stages of development. The main advantages of autonomous vehicles that would also enable logistics providers to offer cheaper deliveries are their scalability, reliability, and high automation potential, combined with progressively increasing levels of independence from human operators. In the next section, we’ll look into the details.

Can autonomous robots reduce the cost of the last mile?

So, are autonomous robots or vehicles a viable option for last-mile deliveries, and can they make the final stretch of the delivery route cheaper?

At the moment, autonomous robots are not yet a scalable solution that can be deployed en masse in most locations, not least because of legislative challenges – but also because of the overall maturity level of the technology. As with many emerging technologies, before they get cheaper, autonomous robots will remain expensive for a period of time, as Peter H. Diamandis points out in his book “The Future Is Faster Than You Think: How Converging Technologies Are Transforming Business, Industries, and Our Lives”.

And indeed, developments aren’t linear but depend on a large number of factors that are interwoven in a complex network – which make exact estimations impossible.

However, major leaps have been made in the past months and years on both sides of the equation, legislation and technology, and large-scale tests and consecutive deployments are getting closer.

LMAD’s robot in Helsinki, Finland during one of our previous pilots

A few factors make robots a good candidate for being a cheaper alternative to current delivery methods. Robots are:

- Automated, reducing labor costs (plus recruitment, management, and HR-related costs)

- Scalable, reducing operating costs

- Electric, eliminating fuel costs (but still dependent on energy costs)

- Convenient for end users and able to deliver 24/7, reducing the amount (and cost) of failed deliveries

So, can robots be a cheaper alternative to existing delivery methods?

Although the exact answer to this question remain speculative (there’s no hard data yet to confirm what the possible cost reductions will be), we’re cautiously optimistic that the answer is yes, last-mile delivery robots can and will provide a viable alternative to current options, and one that will not only be cheaper but also more environmentally-friendly and more convenient for consumers.

According to estimates from McKinsey, at some point in the future, autonomous vehicles will dominate the last-mile delivery market at nearly 100% for deliveries to end consumers (X2C) and at around 80% for deliveries to businesses in the future.

When will this happen, though?

It’s impossible to say, as too many moving parts are involved in the equation — and McKinsey isn’t providing estimates either. In another report, they’re estimating that the technology will be sufficiently mature in a few years from now (5 to 10 years from 2018, the publishing date of the report) for robots to operate with minimal human supervision, which is an important axis of cost reduction.

Nevertheless, last-mile delivery will undoubtedly be taken over by faster, more efficient alternatives to the current options, and it’s only a matter of time to see these options being deployed more and more often.

For that reason, it’s crucial for logistics companies to start experimenting with autonomous deliveries as soon as possible and make sure they’re able to harness their potential and act fast when the conditions become right.

Autonomous robots have the potential to lower the costs of the last mile – although we’re not there yet

Before autonomous vehicles can be deployed at scale, they’ll remain an exotic (or rather, futuristic) alternative to existing last-mile delivery options – but the status quo is unlikely to stay for much longer.

The World Economic Forum is also advising both private and public players to look into possible solutions such as electric vehicles, robots, parcel pooling, and route optimization, to reduce both costs and CO2 emissions, and start their own pilot initiatives as soon as possible to explore options.

Businesses like LMAD, Gim Robotics, TwinswHeel, and many others, are paving the way for last-mile autonomous deliveries, and are receiving the support of both the public sector (via Horizon Europe) and logistics companies such as DHL. Together, they’re working together to develop, test, and deploy viable autonomous alternatives to existing delivery options that will be cheaper, greener, and more convenient.